The process of clothing pattern making

Introduction to the process of garment plate making

What is the process of garment pattern making in clothing production?

Pattern making in garment manufacturing is the process of creating a physical model from a designer’s paper pattern. Through pattern making, the designer can verify the feasibility and practicality of the design, and also allow customers to have a better understanding of the design. Pattern making is an important step in garment production, ensuring accuracy and efficiency in clothing production.

The process of pattern making in garment manufacturing typically involves the following stages:

Profound garment employs professional pattern makers, each of whom must have more than 10 years of experience. Our requirements are so high that in order to guarantee the quality of our customers, contact us to start your project and we will arrange an expert to escort your project.

Pattern making stage

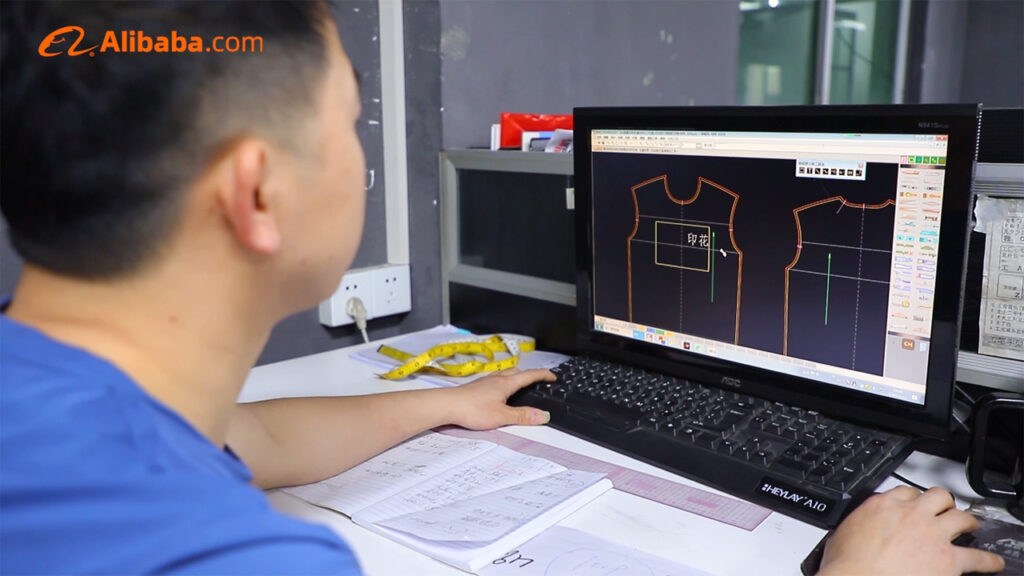

The first step in pattern making is to transform the designer’s paper pattern into a physical template. The process of pattern making involves enlarging the paper pattern to the actual size and drawing out each detail on the pattern. The pattern maker uses CAD software to create the pattern and convert the drawn pattern into a digital format. The pattern maker also needs to determine the hardness and thickness of the template according to the thickness and material of the fabric.

Cutting stage

In the cutting stage, the pattern maker places the template on the fabric and cuts the fabric into various parts needed for making the garment using a cutting knife or automatic cutting machine. The key to this stage is to ensure accuracy and precision in cutting to avoid waste and defects.

Sewing stage

In the sewing stage, the cut fabric is sent to the production line and sewn into a garment according to the established production process. The key to this stage is to ensure accurate sewing of each part while improving production efficiency.

Pressing stage

In the pressing stage, the garment goes through multiple processes such as ironing, shaping, and hanging to give it a better appearance and texture. The pressing process is crucial to the appearance of the garment and can enhance its grade and value.

In summary, pattern making is an important part of the garment manufacturing process, ensuring the accuracy and efficiency of clothing production. The pattern making stage involves transforming the paper pattern into an actual template, while the cutting stage needs to ensure accuracy and precision, the sewing stage needs to ensure accurate sewing of each part, and the pressing stage can enhance the appearance and value of the garment.